Roofing Sheet

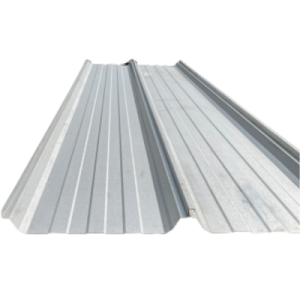

Durakolor Roof Sheet

Our standard product for roofing and cladding is Durakolor Roof, which is also the most widely used profile globally. It has a special construction that allows it to survive bad weather and heavy to torrential rain.

Larger purlin spacing is possible because to its superb load bearing design. To reduce overlaps, it can be provided in lengths of up to 12 metres. There are many colours available, and we can create custom colours for large orders.

It has an anti capillary groove and our proprietary valley discharge function. The water can move more quickly downward due to the valley discharge feature.

The most prevalent roofing technology in use today is seaming. With this profile, even low-sloped structures can be covered without worrying about water seepages. It is capable of withstanding bad weather and heavy to torrential rain. Additionally, it can be utilised with a double skin insulation system.

Additionally, the anti-capillary groove prevents water from entering through the side laps. It can be produced using a variety of raw materials, including bare galvanised steel, coloured galvanised steel, stainless steel, aluminium, etc.

It has a 46 mm high crest and a 480 mm effective covered width. The valley of the sheet has three strengthening ribs, which further increases the sheet’s strength. A powered automatic seaming machine is used to sew.

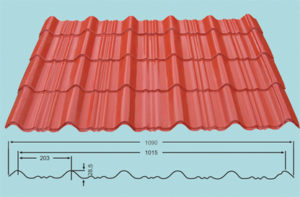

Durakolor Tile Sheet

The Durakolor tile is our customers’ top aesthetic pick; it has a shape similar to the clay tiles used in residential structures. Individual home builders and architects want to give their constructions a more rustic and cosy appearance.

It is available in various colours and densities. Additionally, the lengths can be altered. To further increase the sheet’s strength, two stiffening ribs have been added between two crests. Additionally, it includes our current anti-capillary groove, which stops water seepage from side laps.

Galvalume, an alloy of aluminium and zinc, is used to cover it. Zinc serves as a sacrifice for protection, whereas aluminium serves as membrane protection. In addition, it is painted and primed, which again serves as a barrier and improves the appearance and longevity of the roofing sheet.

It has a 46 mm high crest and a 480 mm effective covered width. The valley of the sheet has three strengthening ribs, which further increases the sheet’s strength. A powered automatic seaming machine is used to sew. We can choose to sew in either a 180 or 360 degree circle.

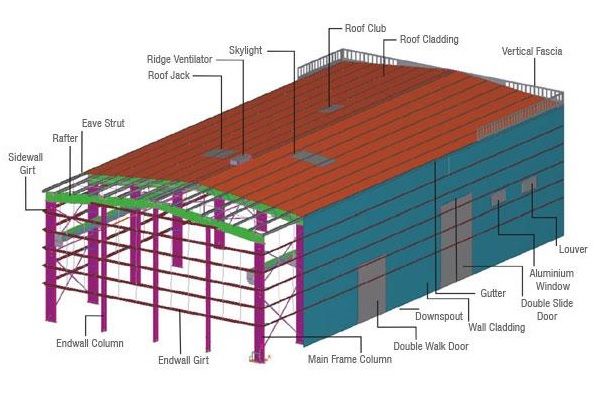

Standing Seam Roofing

The most recent roofing innovation from Techmax Structural is standing seam roofing.It is known as the “screw less” or “hole free” method because special clips with male and female ends are fastened to the purlin and then seamed to the adjacent roofing panel. Since the roofing sheets in this method are not punctured, the customer receives from us a roof that is leak-proof. Because there is no exterior protrusion in the coated roofing sheet’s original factory finish,the interlocking seam of our profile on the side laps extends the life of the roof sheet.There is no restriction on the length of sheet that may be produced as the mobile roofing machine is brought to the location. One sheet can be purchased by customers from his Ridge to Gutter.

Customers may experience the highest quality roofing thanks to our knowledgeable team of site engineers and roofing contractors.

Types of Sheets

Metal Sheet

Plastic Sheet